[ad_1]

Cordless Oscillating Multi-tool – Comparison Testing 2021

The ToolBoxBuzz Crew recently looked at twelve major brands of multi-tools and carefully planned a range of uniquely crafted tests (with some sweet custom jigs) to determine which one was the “Best Cordless Oscillating Multi-tool.”

An oscillating multi-tool is a saw, scraper, sander, and grinder. The tool, as the name suggests, is an all-in-one and versatile tool. A variety of blades/attachments can be used to provide job site solutions to a wide range of cutting and sanding challenges. If this was impressive enough, the consumables are designed to handle a diverse set of materials to include: mild steel, aluminum, carpet, hard tile, soft tile, laminates, hardwood, softwood, and various plastics. So true to form, the Tool Box Buzz team of experts got together to execute some Pro-centric Head-2-Head Testing – And provide the data you’ve come to expect (and crave) from our Head-2-Head tests!

Oscillating Multi-tool History

You may notice that many tradespeople refer to an oscillating multi-tool as a “Fein” tool whether it’s made by Fein or not. There’s good reason for this! Fein invented the tool and for many years they were the only company making OMTs. The origin for this tool is a plaster cast saw that Fein produced in 1967. It was designed to cut hard plaster without cutting a patient’s skin. In 1985 Fein then worked with the automotive industry to adapt this technology to make a tool for cutting silicone to remove panes of window glass from cars. In 1986 the OMT techology was adapted to create the “Fein Grinder” which we now recognize as a delta pad sander. The Fein grinder was the basis for the Fein Multimaster which is the tool that started it all! Once Fein’s patent expire in 2009 the floodgates opened. Oscillating multi-tools went from a niche pro tool only available through direct purchase through Fein, to a mass market tool available in every lumber yard and home improvement center seemingly in a matter of months.

Cordless Oscillating Multi-tool Evaluation Format

For this Best Cordless Oscillating Multi-tool evaluation, our team evaluated a total of 8 essential categories as detailed below. Each of the categories was ranked individually and ultimately used to declare the “Overall Best Cordless Multi-Tool” based on the combined test results.

- Accuracy– The accuracy of the multi-tools was compared including the ability to follow a line and cut splice joints in trim.

- Performance [Power / Speed Test]-We looked at cutting speed through metal and wood as an indicator of saw motor performance.

- Features– An overall comparison of features and specifications.

- Ergonomics– Ergonomics are really important to users and an important category to consider when purchasing any power tool. In addition to traditional ergonomics, we also included functionality in this category.

- Vibration – We analyzed the vibrations of the tools during our speed testing.

- Noise – We used a decibel meter used to measure the tool under no load, and identical cutting load conditions.

- Price– Price is always an important factor in determining which saw is best for a user. We’ve included the current pricing found online for each of the saws “as-tested,” at the time of publication.

- Best Value – Often times this category winner tends to resonate with most folks as it tends to perform well in the tests but feels good on the wallet.

Cordless Oscillating Multi-tool Specifications

Here is the list of specifications for all the Oscillating Multi-tools the Tool Box Buzz Pro team tested in this Head-2-Head:

BOSCH GOP18V-28N

- 18 volt – 4 Ah battery

- 8,000- 20,000 OPM

- 2.55 lbs bare tool and 3.9 with 4.0 ah batt

- Variable Speed

- Oscillation angle 2.8°

- Starlock and Starlock Plus blades

- BOSCH GOP18V-28N

DEWALT DCS355B

- 20V – 4.0 Ah battery

- 0 – 20,000 OPM

- 2.35 bare tool, and 3.75 lbs with 4.0 ah battery

- 3-speed variable speed / VS Trigger

- Oscillation angle 1.6°

- Open back blade

- DEWALT DCS355B

FEIN AMM 700 Max

- 18 V – 3.0 Ah battery

- 10,000-19,500 OPM

- 2.5 lbs bare tool and 3.5 with 3.o Ah battery

- Variable speed

- Oscillation angle 2 X 2,0°

- Starlock Plus and Starlock Max blade

- FEIN AMM 700 Max

FEIN AMM 500 Plus

- 18 V – 3.0 Ah battery

- 11,000-18,500 OPM

- 2.9 lbs bare tool and 4.35 lbs with 3.0 ah battery

- Variable speed

- Oscillation angle 2 X 1,7°

- Starlock Plus blades

- FEIN AMM 500 Plus

FESTOOL OSC 18 E Vecturo

- 18 V – 4.0 Ah battery

- 10,000 to 19,500 OPM

- 2.9 lbs to 4.35 lbs with 4 Ah battery

- Variable speed /Auto setting

- Oscillation angle 4.0°

- Starlock Max blade

- FESTOOL OSC 18 E Vecturo

FLEX FX4111-1A

- 24V – 5.0 Ah battery

- 10,000 – 20,000 OPM

- 2.85 lbs bare tool and 5.5 lbs with 5 ah battery

- 5-speed variable speed

- Oscillation angle 4.0°

- Starlock blade

- FLEX FX4111-1A

MAKITA XMT03Z

- 18 V – 5 Ah battery

- 6,000-20,000 OPM

- 3.1 lbs bare tool and 4.45 lbs with 5.0 ah battery

- Variable speed / soft start

- Oscillation angle 3.2°

- Starlock blade

- MAKITA XMT03Z

METABO 613088850

- 18V – 4.0 Ah battery

- 8,000-20,000 OPM

- .295 lbs. bare tool and 4.2 lbs with a 4.0 ah battery

- Variable speed

- Oscillation angle 1.6°

- Starlock Plus blades

- METABO 613088850

METABO HPT CV18DBLQ5

- 18 V – 4.0 Ah Multi-Volt battery

- 15,000-20,000 OPM

- 3.05 lbs. bare tool and 5.25 lbs. with 4.0 Ah battery

- Variable speed

- Oscillation angle 3.2°

- Starlock and open back blade type

- METABO HPT CV18DBLQ5

MILWAUKEE M18 FUEL 2836-20

- 18 V – 5.0 Ah battery

- 11,000-18,000 OPM

- 2.6 lbs. bare tool and 3.35 lbs with 5.0 Ah battery

- Variable speed

- 4.2°

- Starlock and open back blade type

- MILWAUKEE M18 FUEL 2836-20

RIDGID R86240B

- 18V – 4.0 Ah battery

- 10,000 – 20,000 OPM

- 2.05 lbs. bare tool and 3.65 lbs. with 4.0 ah battery

- Variable speed

- Oscillation angle 3.6°

- Starlock and open back blade type

- RIDGID R86240B

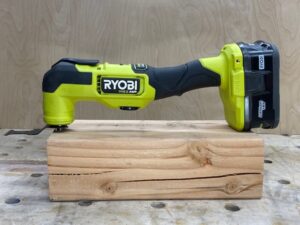

RYOBI P343B

- 18 V- 4.0 Ah battery

- 10,000 – 20,000 OPM

- Variable Speed

- 2.0 lbs bare tool and 3.65 lbs with 4 Ah battery

- Oscillation angle 3.0°

- Starlock and open back blade type

- RYOBI P343B

Imperial Multi-tool Blades

All of the multi-tools tested were outfitted with task-specific, brand new, Imperial multi-tool blades. This ensured that the focus was on the tools and not the blades. Using standardized blades throughout the test also helped maintain consistency since it removed an outside testing variable. Imperial blades are a crew favorite and have been a go-to blade for years on our construction sites. Imperial was also able to supply blades that fit all of the blade clamp/mount types as well as the material-specific blades we required for our testing.

Imperial Blades Used:

- Bi-metal Wood with Nails

- Hardwood

- Carbide

The Imperial blade interfaces included Starlock, OIS, and “Open-back” compatible blade mounts. This range of mounting interfaces was critical to ensuring a universal match with all the Multi-tools tested. Of note, some of the Multi-tools tested are compatible with multiple blade mounting interfaces giving them increased blade selection options.

Cordless Oscillating Multi-tool Accuracy

Oscillating multi-tools are extremely adaptable. Everything from rough frame to metal cutting, sanding, and trim carpentry can be accomplished using an oscillating multi-tool. There are times in carpentry where accurate multi-tool cuts matter. Our Pro crew also frequently uses oscillating multi-tools when completing exterior trim repairs. These trim cuts can be the difference between a clean splice joint or a jagged, ugly joint.

For our accuracy test, we asked one experienced user to use every multi-tool to freehand cut cedar bevel siding (sometimes called clapboards) in place and to cut a 1×6 pine corner board in place using a jig and then assess and rank the tools based on their performance. We purposefully had a single operator execute this to better control the test standardization. Our assumption was that multiple users might have slightly different techniques, and therefore results, as compared to a single Pro operator.

Range of test criteria:

- Accuracy: Ease of controlling the tool and how clean a cut did the OMT produce.

- Vibration: A subjective assessment of how much the tool vibrated during use and if the vibration negatively impacted the accuracy and cleanliness of the cut.

- Ergonomics: Related to control/accuracy, an assessment of how comfortable the tool was to hold and use while performing these tasks. A good grip can make or break a tool, while a poorly placed knob or lever or a slippery hard to hold tool can negatively impact control and accuracy.

- Power: A tool with adequate or better power allows greater control by minimizing the amount of pressure the user has to use to complete the cut. “Let the tool do the work” is much easier when the tool has good power!

| Manufacturer | Rank |

| Fein 500 | 1 |

| Fein 700 | 1 |

| Festool | 1 |

| Flex | 2 |

| Makita | 2 |

| Milwaukee | 2 |

| Metabo HPT | 3 |

| Metabo | 4 |

| Bosch | 5 |

| DEWALT | 5 |

| Ridgid | 5 |

| Ryobi | 5 |

Best Cordless Oscillating Multi-tool Accuracy Winner – Fein 700, Fein 500, Festool

There was a three-way tie for the winner of the multi-tools accuracy-test between the Fein 700, Fein 500, and Festool Vecturo, with almost identical results during accuracy testing as a result of the very similar overall designs and performance.

The Flex, Makita, and Milwaukee came in a three-way tie for second. But all due to slightly different standout design reasons. The Flex has a good grip, with rubber pads on each side of the head. This provides excellent overall control. The grip design complements solid power and when paired with its vibration-damping decoupled design, provided great overall accuracy.

The Makita has a generous amount of rubber over-mold and very effective decoupling to provide excellent grip and control, and therefore excellent cuts. While the Milwaukee has decoupling and a decent grip the power of this tool made it cut through the corner board like a hot knife through butter. And in this case, a fast cut also made for a cleaner, more accurate cut.

The Metabo HPT was a surprise stand-out in this category. While it doesn’t have a decoupling design feature (which all 6 tools above have), its oscillation action was very smooth and the tool was easy to control. This led to solid overall accuracy and provided a surprisingly smooth cut.

Performance Testing (Power/Speed) (Wood/Metal) – Winner Milwaukee

An obvious question when comparing the performance of different multi-tools is “which saw cuts the fastest?” This test also equates to power and power equates to cutting thicker, and or, harder-to-cut materials.

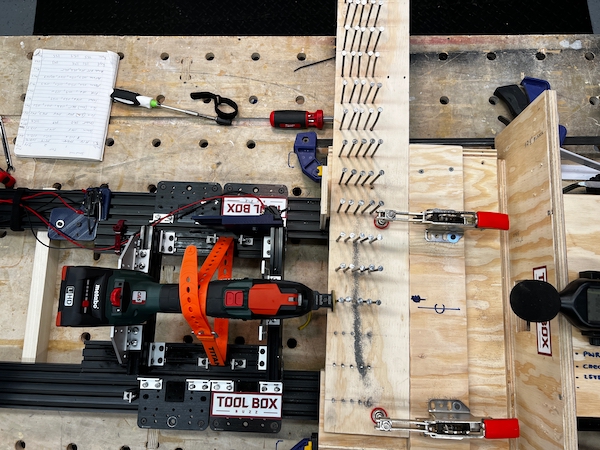

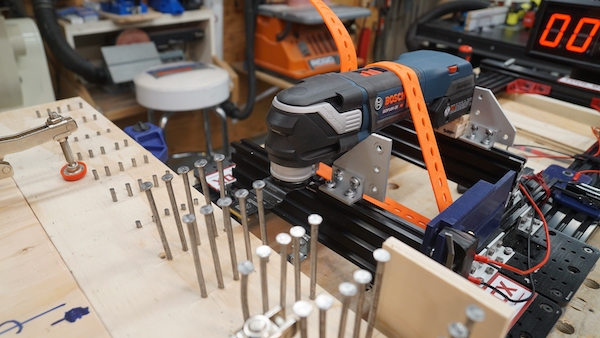

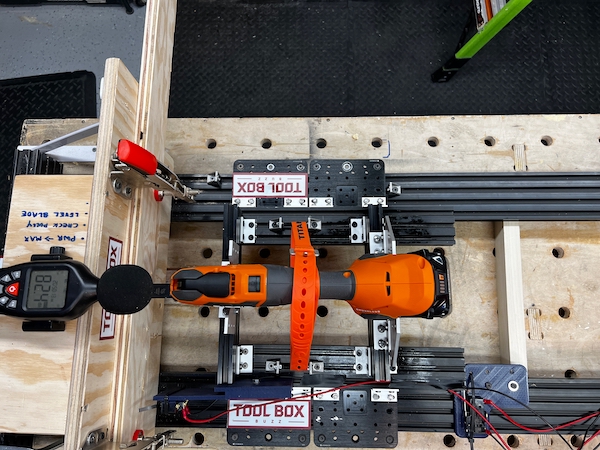

Recognizing that using a multi-tool requires the operator to make dozens, if not hundreds, of minuscule adjustments during each cut we decided to try to eliminate the human variable. To test the power, we built a jig to hold the saws and complete two tests:

- Test 1: pull the saws into 3/4″ plywood using a weighted pulley system.

- Test 2: cut five 16-penny framing nails using a weighted pulley system.

In the TBB jig, we supported the plywood on a frame, that in turn was held to the workbench by clamps. The tools were leveled and strapped to the test fixture.

We used this jig to remove as much human variation as possible to allow for the fairest test possible. We used a rope and pulley system to transfer a 5.5 lb weight into a constant 5.5 lb horizontal force for each and every cut. All saws had variable speed motors and the highest oscillating speed was selected for the tests.

Weighted Pulley System

The pulling force was provided by a weighted pulley system which pulled the multi-tools through the material with consistent force. This approach has 2 main benefits:

- First, it allows a constant force to be applied to each multitool in the same way that an operator tries to apply a constant force while cutting.

- Secondly, by allowing for natural resistance (as opposed to forcing a constant cutting speed via mechanical motors) it allows the saw to cut at its natural maximum speed based on the maximum oscillations per minute and the power of the motor. This also underscores the importance of using the same blade types on all of the saws.

The sled fixture held the multi-tools securely and level while the aluminum tracks kept the saw moving in a consistent and parallel fashion. The saws were in contact with the sled and the sled in contact with the workpiece. During the course of testing, the fixture performed with no issues. An automatic timer with contact switches was used to start and stop the timer for each test. Removing the human error element of a handheld stopwatch.

All the tools selected for this test were members of the 18V-24V high-performance line supplied by each manufacturer. Batteries supplied ranging from 3 to 5 amp-hour capacity. In the previous head-to-head test, we’ve normalized the field by considering the size of the batteries (Amp Hour) and Voltage of the platform to calculate the Watt-Hour of each tool tested. This is particularly critical when performing endurance or run-time tests where you are testing the amount of work a tool can perform on a single battery charge. In this test, we are testing for speed and power, not work capacity. Thus the Watt Hour considerations you may have seen from us in the past are not used here.

Performance Testing (Power/Speed) in Wood – Winner Milwaukee

One of the most common, if not THE most common materials on a construction site is plywood. So for our Power/Speed test, we used our Multi-tool jig to test each tool’s cutting speed through 3/4″ plywood. Three runs were performed for each tool and their times were averaged.

Milwaukee came in first place with an average of just 4.18 seconds per cut. Milwaukee claims to have the fastest cutting saw and from what we saw in testing, their tool delivers on that promise.

The second and third-place finishers were Ryobi with a 6.11 average cut time and DEWALT with a 6.11 cut time. Both these tools cut through the material exceptionally well. The rest of the rankings can be found in the following chart.

Wood Cutting – Use testing sled rig to cut 3/4 plywood under steady load

| Manufacturer | Avg Time | Rank |

| Milwaukee | 4.18 | 1 |

| Ryobi | 6.11 | 2 |

| DEWALT | 7.45 | 3 |

| Rigid | 9.77 | 4 |

| Flex | 16.58 | 8 |

| Makita | 17.03 | 9 |

| Festool | 14.00 | 5 |

| Bosch | 14.05 | 6 |

| Metabo HPT | 19.03 | 10 |

| Fein 700 | 15.70 | 7 |

| Metabo | 24.06 | 11 |

| Fein 500 | 29.89 | 12 |

Winner of Metal Cutting – Milwaukee

To test the tools against metal, a series of five 16-penny nails were arranged in a series in a straight line. The nails were located close together to minimize the slamming of the tool into the material and damage blade teeth. The timer was started just before the first nail was contacted and immediately after the fifth nail was cut.

It’s always nice to see consistency across performance tests and the top three tools managed to do just that. The fastest cutting tool was again the Milwaukee at 17.06 seconds, followed by the Ryobi at 26.61 seconds and the DEWALT in third at 28.68 seconds.

Perhaps the biggest surprise of the bunch was the Ryobi, dethroning all but one tool in the performance rankings. As the lowest cost option of the group, the Ryobi boasts some serious cutting prowess.

Metal Cutting – Use testing sled rig to cut 5 nails/screws in sequence under steady load

| Manufacturer | Avg Time | Rank |

| Milwaukee | 17.06 | 1 |

| Flex | 29.35 | 4 |

| Ryobi | 26.61 | 2 |

| Makita | 34.7 | 5 |

| DEWALT | 28.68 | 3 |

| Rigid | 34.78 | 6 |

| Bosch | 38.72 | 8 |

| Festool | 39.97 | 9 |

| Fein 700 | 36.49 | 7 |

| Fein 500 | 42.86 | 10 |

| Metabo | 79.07 | 11 |

| Metabo HPT | 97.72 | 12 |

Best Cordless Oscillating Multi-tool Features – Winner FLEX

It’s never easy to compare tool features from different brands, but the devil is in the details, thus a feature comparison is necessary.

The entire team used all of the tools in a variety of cutting configurations and tests to rate four separate features on these saws on a scale of one to five. [With 1 being the best]

Features that we looked at:

- Blade Change

- LED Light

- Decoupling

- Variable Speed

The number one slot for features went to the newcomer, the FLEX Multi-tool with 8-points. FLEX had the best wraparound LED light coverage, excellent vibration decoupling and scored second in blade change and third in its variable speed adjustment.

A close second place went to Milwaukee with 9-points. The Milwaukee has low cutting vibration, excellent LED, and variable speed with auto-setting. Third place was a three-way tie [10-points] with both FEIN tools and the Festool Multi-tool. These tools were extremely smooth cutting [low-vibe] and, along with the Bosch, sported the best style blade clamps and blade changing system.

| Manufacturer | Variable Speed | LED | Decoupling/ Anti Vibe | Blade Change | Sum of Scores | Rank of Scores |

| Flex | 3 | 1 | 1 | 3 | 8 | 1 |

| Milwaukee | 2 | 2 | 1 | 4 | 9 | 2 |

| Fein 500 | 3 | 5 | 1 | 1 | 10 | 3 |

| Fein 700 | 3 | 5 | 1 | 1 | 10 | 3 |

| Festool | 3 | 5 | 1 | 1 | 10 | 3 |

| DEWALT | 1 | 3 | 5 | 2 | 11 | 4 |

| Makita | 3 | 4 | 1 | 4 | 12 | 5 |

| Bosch | 3 | 4 | 5 | 1 | 13 | 6 |

| Ryobi | 3 | 3 | 5 | 3 | 14 | 7 |

| Metabo | 3 | 3 | 5 | 4 | 15 | 8 |

| Rigid | 3 | 4 | 5 | 3 | 15 | 8 |

| Metabo HPT | 2 | 4 | 5 | 5 | 16 | 9 |

Stand Out Features

There were a few stand-out features that affect performance and safety. While not all of the multi-tools had stand-out features, we broke down a few that matter.

Blade Change

All of the multi-tools can use the base Starlock and several can also use the open back blades. The exception is the DEWALT, which can only use open back, due to its spring lever system.

Slide & Click Lock – Bosch, Festool, and Fein

These multi-tools require the user to simply push the blade into the tools blade accessory holder. It’s fast, easy and the team feels it is far superior to the other methods.

One thing we noted during testing was that the Festool power switch is easily actuated to the on position when changing the blade. The user needs to be careful when reaching for the blade change lever, so the thumb can easily hit the power switch.

Lever-Based Lock – DEWALT

The team rated the DEWALT’s blade clamp mechanism as having the second-best blade change system. This system is effective, but the spring tension on the clamp can be difficult for some users to actuate. Overall, the team felt that the DEWALT clamp was not a bad design.

The FLEX multi-tool has a similar Starlock mechanism to the Fein and Festool but the locking mechanism requires the user to use the locking lever. This lever spring is very aggressive when returned to lock position and likely to bruise the user’s knuckles.

Lever Lock & Locking Clamp – Ridgid and Ryobi.

This locking clamp is permanently attached and will not fall out of the tool.

When you’re in a tight spot to rotate the blade to get at a particular angle with the multi-tool, ideally you’d be able to rotate the blade without having to manipulate the locking clamp. This may be an intentional design decision but one that the team feels is a pain point in the field. Having more throws on the locking clamp could resolve this issue.

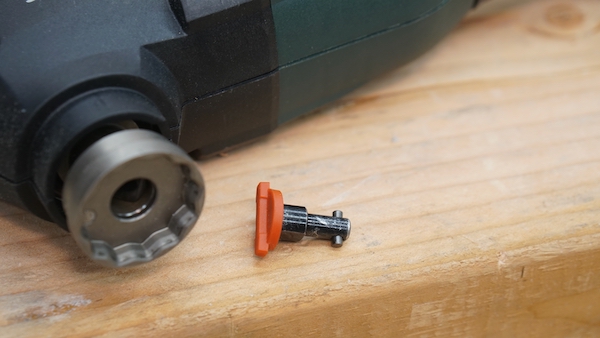

Pin & Lever System – Metabo, Metabo HPT, Milwaukee, and Makita

The Metabo multi-tool design is set up that the pin can fall out during storage, even with the lever closed, requiring you to keep a blade in the tool in order to lock the on in place. One nice feature is that you can adjust the blade without removing the pin – something that the team feels is important in the field.

The Metabo HPT has a 3-step blade change process. It has a lever, pin, and a locking twist collar. It is not easy to use and the team felt it was the worst blade clamp set up.

LED Light

The best light was on the FLEX due to its ability to completely illuminate the blade at 90-degrees, Milwaukee was a close second with its super bright 3-LED array, which also provides some peripheral side lighting.

The Bosch, Metabo HPT, and Ridgid multi-tool lights do not stay on after the power switch is turned off. The Feins and Festool do not have LED lights, something that seems so simple to add.

Decoupling

Fein, Festool, FLEX, Makita, and Milwaukee have decoupling setups on the working end of the tool.

Variable Speed Control

Metabo HPT and Milwaukee have Auto settings on the variable-speed dials that allow you to set the upper limit of motor speed but start your cut at a lower RPM until your into the cut. The team favored the auto setting in the field as it allows you to slowly start your cut and power up once your kerf is established.

The DEWALT is the only multi-tool that offers a variable-speed trigger to allow you to vary the speed of the saw according to how hard you pull the trigger or where the speed adjustment 3-step mechanical, the setting is set.

The FLEX was unique with its 5-step digital, push-button, variable speed setting. It’s super easy to use and does not lend itself to accidental changing of setting.

Ergonomics is the science of designing and producing tools that improve a worker’s efficiency while reducing discomfort, fatigue, and risk of injury.

Ergonomics Winner – Fein 700

Our pro team members evaluated each tool under a simulated/real-world test setup. Materials cut included drywall, clapboard, plywood, pine trim, baseboard freehand, and a “splice” jig. We also used the tools to free-hand cut 16D common nails and drywall screws.

| Manufacturer | Grip | Vibration | Balance | Total Scores | Rank |

| Fein 700 | 2 | 2 | 1 | 5 | 1 |

| Fein 500 | 2 | 2 | 2 | 6 | 2 |

| Festool | 2 | 2 | 2 | 6 | 2 |

| Milwaukee | 1 | 2 | 4 | 7 | 3 |

| DEWALT | 1 | 5 | 3 | 9 | 4 |

| Metabo | 1 | 5 | 3 | 9 | 4 |

| Bosch | 3 | 5 | 2 | 10 | 5 |

| Flex | 5 | 3 | 3 | 11 | 6 |

| Makita | 5 | 2 | 4 | 11 | 6 |

| Metabo HPT | 2 | 5 | 5 | 12 | 7 |

| Rigid | 4 | 5 | 4 | 13 | 8 |

| Ryobi | 4 | 5 | 4 | 13 | 8 |

In laymen’s terms, ergonomics is the interface between the user and the tool. How’s it feel when using it? For this ergonomic section, we considered the following factors, rating them 1 thru 5. [1 being best]

Ergonomics Factors

Regardless of how fast a multi-tool cuts, the less vibration it produces, the better. Some multi-tools employ some sort of decoupling system to reduce vibration. The FEIN 700 multi-tool scored tops in balance and came in at 2-points for vibration and balance. Second place was a tie between the FEIN 500 and the Festool – both scoring 2nd place in all three categories. Third place went to Milwaukee and was noted well balanced.

Noise – Winner FEIN 500

OSHA allows 8 hours of exposure for up to 90 dB, for exposures 95dB and greater, the exposure limits drop dramatically. So clearly these saws all need hearing protection.

We used a fixed Decibel Meter to measure these multi-tools in the following workshops tests and ranked them on that average score:

- No-load

- Metal cutting

- Woodcutting

The quietest saw was the FEIN 500 averaging at 106.5 decibels followed by the Metabo at 106.7 decibels and the FLEX at 106.8.

| Manufacturer | No Load | Metal | Wood | Average | Rank |

| Fein 500 | 94.2 | 112.9 | 112.3 | 106.5 | 1 |

| Metabo | 94.9 | 113.2 | 112.03 | 106.7 | 2 |

| Flex | 97.1 | 111.1 | 112.2 | 106.8 | 3 |

| Makita | 91.5 | 116.6 | 113.8 | 107.3 | 4 |

| Metabo HPT | 97.1 | 113.3 | 112.0 | 107.5 | 5 |

| Festool | 95.7 | 118.9 | 113.9 | 109.5 | 6 |

| Ryobi | 99.7 | 116 | 115.5 | 110.4 | 7 |

| DEWALT | 103.0 | 114.8 | 114.6 | 110.8 | 8 |

| Fein 700 | 102.5 | 115.6 | 114.6 | 110.9 | 9 |

| Milwaukee | 104.2 | 118.1 | 113.3 | 111.9 | 10 |

| Rigid | 104.0 | 117.1 | 115.1 | 112.1 | 11 |

| Bosch | 105.6 | 119.6 | 114.2 | 113.1 | 12 |

Price

Below we’ve included the current pricing (at the time of publication). Pricing is based on the bare tools where available. We chose the bare tool because a multi-tool is typically a secondary tool to one’s tool arsenal and one typically purchased to compliment an already established battery platform.

The only tool that is NOT available as a bare tool is the FLEX multi-tool. The most affordable tool is the Ryobi but the real surprise is how many of the “higher-end” tools are in the $150 range.

| Manufacturer | Model | Price | PRICE RANK |

| Ryobi | P343B | 49 | 1 |

| Milwaukee | 2626-20 | 109 | 2 |

| Metabo HPT | CV18DBLQ5 | 114.99 | 3 |

| Makita | XMT03Z | 119 | 4 |

| Ridgid | R86240B | 129 | 5 |

| DEWALT | DCS355B | 139 | 6 |

| Bosch | GOP18V-28N | 151.8 | 7 |

| Metabo | 613088850 | 179 | 8 |

| Fein | 71293362090 | 183 | 9 |

| Fein | 71293462090 | 199 | 10 |

| Flex | FX4111-1A | 199 | 10 |

| Festool | OSC18 | 375 | 11 |

The best-priced cordless multi-tool was the Ryobi at $ 49 Second place was the Milwaukee priced at $109 followed by Metabo HPT at $115. The highest-priced saw in this testing was the Festool which sells as a bare tool for $375.

Best Cordless Multi-tool Winner –Milwaukee

The competition for the best cordless multi-tool went to Milwaukee M18 FUEL multi-tool, with 19-points. Milwaukee crushed its competitors in the controlled wood and metal testing rig. It scored well in the accuracy and features sections coming in second place in both and taking third place in ergonomics.

Second place went to the FLEX multi-tool, with 24-points, which surprised the team. The FLEX is a feature-rich tool and came in first in that section. Scoring second in accuracy and third in the decibel testing, the FLEX solidly secured its position as the second-best tool in the testing. It was also the fourth-fastest cutting tool in metal.

Third place went to the Festool with 26-points. The Festool came in first for accuracy, second in ergonomics, and third in features rankings. Festool has the best blade clamp of the top three contenders and is a top-tier, easy-to-use, and intuitive saw.

| Manufacturer | Wood Cut | Nail Cut | Noise | Ergo. | Featrs. | Accur. | Total | Final Ranking |

| Milwaukee | 1 | 1 | 10 | 3 | 2 | 2 | 19 | 1 |

| Flex | 8 | 4 | 3 | 6 | 1 | 2 | 24 | 2 |

| Festool | 5 | 9 | 6 | 2 | 3 | 1 | 26 | 3 |

| DEWALT | 3 | 3 | 8 | 4 | 4 | 5 | 27 | 4 |

| Fein 700 | 7 | 7 | 9 | 1 | 3 | 1 | 28 | 5 |

| Fein 500 | 12 | 10 | 1 | 2 | 3 | 1 | 29 | 6 |

| Makita | 9 | 5 | 4 | 6 | 5 | 2 | 31 | 7 |

| Ryobi | 2 | 2 | 7 | 8 | 7 | 5 | 31 | 7 |

| Metabo | 11 | 11 | 2 | 4 | 8 | 4 | 40 | 8 |

| Bosch | 6 | 8 | 12 | 5 | 6 | 5 | 42 | 9 |

| Rigid | 4 | 6 | 11 | 8 | 8 | 5 | 42 | 9 |

| Metabo HPT | 10 | 12 | 5 | 7 | 9 | 3 | 46 | 10 |

Best Value Cordless Oscillating Multi-tool– Winner Flex

As a new brand, the Flex was an unknown to the team and it surprised and impressed everyone. The Flex is the only tool in the field however that is only sold as a kit. While this can be frustrating to those looking for a bare tool, as a new tool brand most people looking to buy into the platform will likely require batteries and chargers. The kit with battery and charger retails at $199. The battery and charger if purchased individually would cost $160 alone, pricing the bare tool in the $40 -$50 range. Couple that with a lifetime warranty, and you have an outstanding value for new users.

It’s hard not to be the best value tool when you take first place and your tool costs $109.00. The second best value tool in this evaluation was the Milwaukee M18 FUEL multitool.

It is a top-tier, solid performer and is offered at a good price making this saw the best value multitool.

Conclusion

This is the MOST COMPREHENSIVE data on the market. Our ALL-Pro contractor team dedicated a significant amount of time and effort to our Best Cordless Multi-tool Head-to-Head comparison in order to provide you with the most thorough data possible.

Because we’re not a professional testing company and have limited time to assess the tools, these tests and evaluations are tough, time-consuming, and ultimately limited in scope. We can’t undertake long-term testing to determine longevity, and we can’t possibly test every application that one of these saws could be used for.

We get a lot of questions regarding how we come up with the final rankings. As previously noted, comparing tools can be done in a variety of ways. The good news is that we’ve made ALL of our test data publicly available, and you can rate the tools any way you wish. Don’t care about an item we ranked? No problem. Simply take that out of the matrix and re-rank them. When evaluating cordless multi-tools, we hope you’ll find this Head-to-Head comparison beneficial.

If you have a moment, please check out our other Head-to-Head Tests.

Buy Now From Our Sponsored Retailers

[ad_2]

Source link